Commercial News

Thun, 11 March 2019

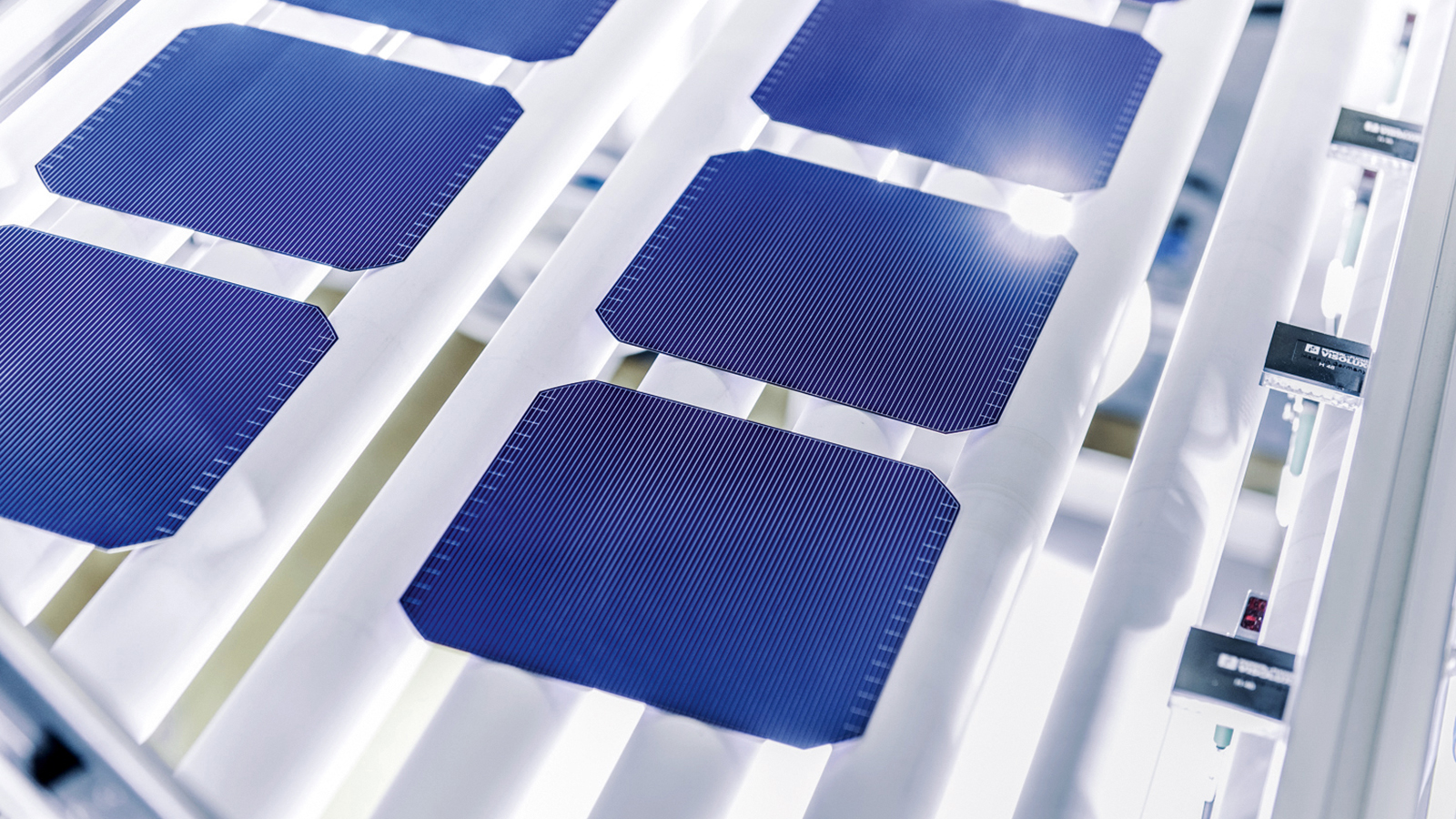

Meyer Burger announces record HJT cells with efficiencies over 24% at PV CellTech

Heterojunction – Meyer Burger’s flagship technology

At PV CellTech 2019, international PV industry leaders will discuss key issues driving the development of solar cell production in the coming years. Meyer Burger CTO, Dr Gunter Erfurt, has been invited to present to a high-level session focusing on Heterojunction (HJT) cell expansion and its potential as a breakthrough technology for multi-gigawatt mass production in 2019. With its focus on the development of industrialized high efficiency Heterojunction manufacturing solutions, Meyer Burger has already achieved HJT cells with recent record efficiencies of over 24.2% on its standardized HJT equipment. A technology roadmap for HJT cells with efficiencies towards 25% is already in place at Meyer Burger. During his presentation, Dr Erfurt will include an update on Meyer Burger’s successful SWCT® cell connection technology for which over 1 GW has already been sold.

Dr Erfurt was also asked to speak on passivated contact solar cells (also known as TOPCon or monoPoly®) and what is required for this technology to become a mainstream offering in the PV industry during the keynote session at PV CellTech. Today the prevailing mainstream technology in the photovoltaic market is PERC (Passivated Emitter Rear Contact) cell coating technology. Current PERC solar cells achieve efficiency levels of between 21% and 22% but there are significant technology limitations, which affect the potential for further increases in PERC cell efficiency. Passivated contact technology can offer an evolutionary upgrade to existing PERC mass production capacities, taking them to efficiency levels around 23%.

CAiA® – Meyer Burger’s new platform to drive TopCon industrialization

For the past two years, Meyer Burger has been developing a platform for the industrialized manufacture of solar cells with passivated contact technology for both n- and p-type wafers. In trials with customers, the CAiA® platform has already produced cells with efficiencies slightly above 23% and the first lab machine has already been sold to a strategic customer and technology partner, with initial installations planned by midyear. The CAiA® ideally complements Meyer Burger’s industry leading MAiA® and FABiA® cell coating portfolio with both current as well as new customers benefitting from a combination of the CAiA® together with either the MAiA® or FABiA® as the optimal solution for the manufacture of passivated contact cells. Meyer Burger’s SWCT® module technology is the ideal solution not only for HJT modules but also for the most cost-effective production of solar modules with passivated contact cells.

Patent infringement claim by Hanwha Q Cells

Recently solar module manufacturer, Hanwha Q Cells, submitted a patent infringement claim against several Asian solar module producers for the use of Atomic Layer Deposition (ALD) passivation technology. Meyer Burger’s MAiA® and FABiA® cell coating platforms use the company’s proprietary Plasma Enhanced Chemical Vapor Deposition (PECVD) passivation technology, which is the leading alternative technology to ALD and thus not in the scope of the patent infringement claim by Hanwha Q Cells.

Contacts:

Ingrid Carstensen

Head of Corporate Communications

Tel.: +41 (0)33 221 28 34

ingrid.carstensen@meyerburger.com

Stefan Diepenbrock

Corporate Communications

Tel.: +41 (0)33 221 27 85

stefan.diepenbrock@meyerburger.com